Motor Repair Best Practices Pt. 4 – Polarization Index Testing

What is a Polarization Index test?

The polarization index test is one of the most misunderstood, and sometimes misapplied, of all electrical tests. This post will summarize some of the changes to the test over time and provide insight as to how it should, and should not be used.

The polarization index (PI) is used as an indicator of motor insulation health, and is useful in identifying accumulation of contaminants as well as physical change in the insulation. From a standpoint of physics, to polarize is to cause something to obtain polarity. The test involves applying a positive charge to motor conductors and a negative charge to the motor frame, therefore polarizing the insulation. The test effectively measures a change current over time.

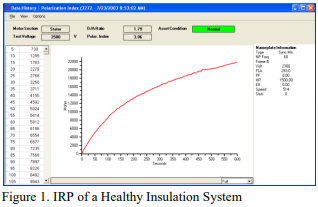

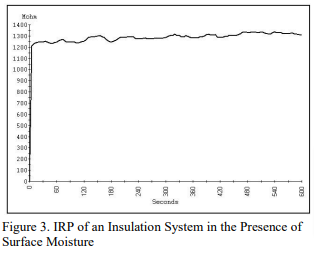

Due to absorption properties, healthy and clean insulation will “charge” over time, reducing the amount of current. This is recorded as an increase in resistance. Unhealthy insulation will not exhibit this characteristic, resulting in a flat curve.

Changes in the Polarization Index Test (standard)

The applicable standard for the test is IEEE 43, which was updated in 2000 and in 2015. Prior to that, things were simple. A standard insulation resistance test was taken, observing the resistance of the insulation at 60 seconds and then at 10 minutes. The 10 minute value should exceed the 1 minute value by a factor of two or more (see IEEE 43 and EASA AR100 for specifics).

But things change, and so do insulation technologies and instruments. In the 2000 update, IEEE made provisions to recognize for example that some insulation systems charge very quickly, and thus the reading may not be meaningful. As mentioned in a great article by Howard Penrose, “additional concerns were outlined in the update, including temperature limitations, dew-point limitations, trending tests, surface conditions, types of windings to be tested, and more.”

Applying the Polarization Index test

With so many variables to consider, applying the PI test has become more like diagnosing a rash than taking a temperature. It is not therefore best applied as an actual acceptance test. However, there are two guidelines that can make the application of the test a bit more straightforward.

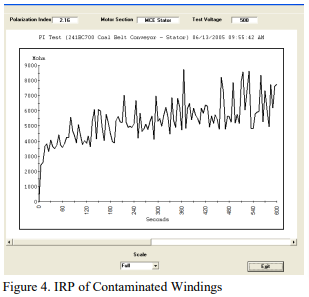

- Graph the test instead of simply capturing the numeric index. Use a good meg-ohm meter or instrument that features graphical recording. A good PI will show a smooth curve, leveling off after its peak. A suspect winding will show limited absorption, patterns of discharge, and other visible patterns. These are indicative of contamination, embrittlement, and other insulation problems.

- Whether in the field or in the shop, the test should be used in conjunction with other methods, such as step voltage testing, to make an assessment. Trending is also very helpful, particularly in the field.

A good PI indicative of a clean and healthy winding.

An erratic graph indicative of moisture and/or contamination.

Per IEEE, this index exceeded 5000 meg-ohms very quickly and would be discarded. Note how the graph provides much greater insight into what appears to be a problem.

Images courtesy of PdMA.

As mentioned above, it is good to have equipment that both graphically trends the PI, and combines testing methods. In practices, we use Baker AWA and PdMA for analysis purposes. The AWA carries the brunt of in-shop testing, including surge testing. We deploy the PdMA in the field and trend many variables as part of diagnostic history, including resistive, inductive, and capacitive imbalances.

Wrap up

In summary, without getting overly technical, here are a few tips your motor shop should observe in applying the test in the field, or in the shop.

- With the changes to IEEE 43 in 2000, PI tests require much more interpretation.

- The PI test can indicate a problem, but it is not a stand-alone acceptance test.

- A graphical recording of the PI is much more helpful.

- The PI is best used in conjunction with other tests.

David L. McKinnon at PdMA wrote a great paper (profiling IR) on the benefits of the graphical PI test. We included it here for convenience. PdMA graphical PI profile.

PI Testing Video

Polarization Index testing or PI testing is often misunderstood and misapplied. it’s a highly useful test to determine the health of motor insulation and in so doing, identify accumulations of contaminants and assess the physical health of the insulation. In short, polarization means to cause something to obtain polarity and this test causes molecules to move toward a given pole in the motor.

In the motor shop, we apply a positive charge to the motor conductors and a negative charge to the motor frame. This video highlights the testing procedure, changes over time that have altered those procedures, why you should use PI testing with other test methods, and how to think about your PI test results.

PI testing video explains things you should do

In the past, PI testing was all about taking a standard insulation resistance test at 60 second and again at 10 minutes. It was an accepted fact that the 10 minute value should exceed the 1 minute value by a factor of two, or more. IEEE recognized that changes motor insulation required a more in depth test. Here are four tips that will improve the quality of your PI tests, whether they are performed in the field, or in the motor shop. The video will help you understand the following.

- Why PI tests require much more interpretation.

- Learn why PI tests are not good stand alone acceptance tests

- Why is graphical recording of the PI more helpful

- What other tests should be used in conjunction with PI tests.